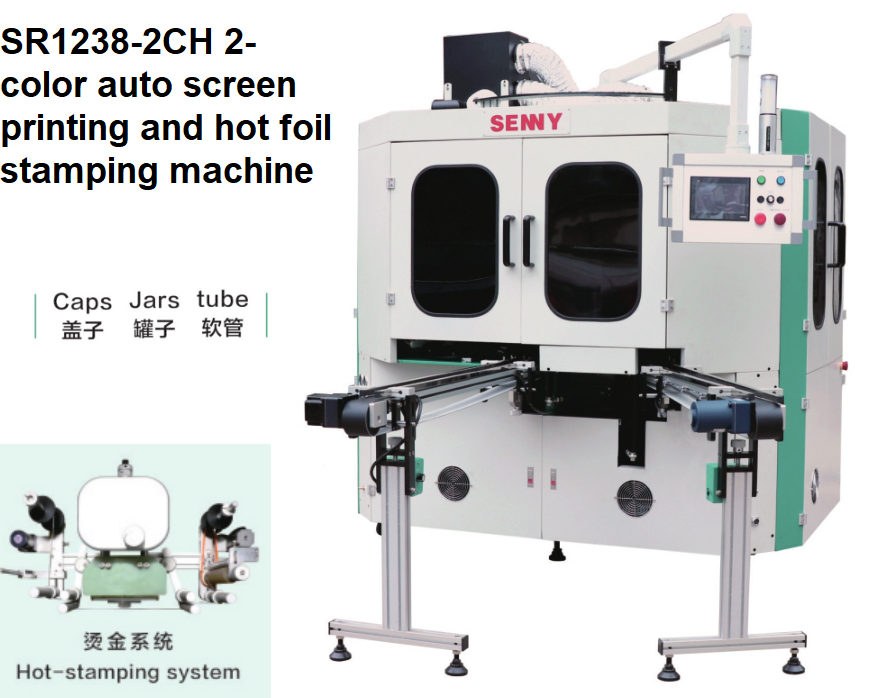

2 Color Digital Foil Hot Stamping Machine 2000pcs/Hr Round Containers

Product Details:

| Place of Origin: | China |

| Brand Name: | Senny |

| Certification: | CE SGS |

| Model Number: | SR1238-2CH |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1PC |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Plywood package |

| Delivery Time: | One Month |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 10PCS /month |

|

Detail Information |

|||

| Printing Color: | 2 Colors | Plate Type: | Screen Printer |

|---|---|---|---|

| Printing Durability: | High Durability | Hot Stamping Color: | 1 Color |

| Warranty: | 1 Year | After-Sales Service: | Video Or On-line |

| Package Details: | Plywood Package | Payment Terms: | T/T |

| Certification: | CE | ||

| Highlight: | digital foil hot stamping machine,hot stamping machine for round containers,high-speed hot stamping machine 2000pcs/hr |

||

Product Description

2 Color Digital Foil Hot Stamping Machine For Round Containers 2000pcs/Hr

Technical Specification:

| Product diameter | Φ20-Φ80mm |

| Product height | 20-200mm |

| Printing Speed | Up to 3000pcs/hr |

| Max Printing Area | L250mmxW150mm |

| Max screen frame size | L450xW250mm |

Features:

1. Few tools, simple operation, low maintenance cost and high accuracy. High precision of color-to-color registration.

2. Servo motor control, equipped with various monitoring systems to ensure the stability and safety of the machine when running at high speed.

3. According to the product characteristics, the machine is equipped with hot stamping system, which can also be customized according to your specific requirements.

4. Machine size and color can be customized.

5. The machine is designed with high precision (tolerance control less than 0.2mm) automatic screen overprinting and hot stamping. It adopts independent servo frequency conversion speed control device. Printing speed up to 3000 pieces per hour. Servo gearless design, faster and easier fixture replacement, less wearing parts.

Applications:

This machine is a multifunctional rotary multi-color screen printing machine. It is mainly used for printing on hoses, cans and bottle caps. It is characterized by simple operation, accurate positioning, high degree of automation and fast printing speed.Thanks to its rotary workflow (each station operates simultaneously), the machine can achieve a maximum printing speed of 300–500 workpieces per hour (depending on the number of color layers and workpiece size). For example, when printing 3-color patterns on standard 30mm-diameter hoses, the hourly output can reach 450 pieces—3–5 times faster than traditional manual or semi-automatic screen printing machines, significantly shortening production cycles for large-batch orders.

![]()

Printing samples

![]()

![]()

Exhibition

![]()

About us:

SENNY PRINTING EQUIPMENT CO.,LTD was established in the year 2004, it is specialized in designing and manufacturing precise automatic screen printing machines, stick labler machines, hot stamping machines and auxiliary equipments. Meanwhile, they can design any kinds of automatic printing machines according to customers' requirements.

SENNY has very good designers. The founder of SENNY was engaged in designing and developing screen printing machines early from the year 1994, and he got many achievements: he designed the first automatic screen printing machine; automatic screen printing machine for big iron pails; four colors sereen printing machine for big oil kettles; automatic screen printing machines controlled by module independently for bottles; automatic screen printing machine for pails from 10L 1o 20L(3colors and 7colors) and so on so forth.

In order to improve our products, SENNY adopts the advantages of the similar products in or abroad, and we also take customers' comments and suggestions into consideration. With the innovation and improvement for many years, the products produced by SENNY now are in a leading position in the domestic markets. And it also sales well all around the world.

With the mission“Excellence,Creation,Sincerity,Quality!”,SENNY insists on providing high--quality products and services, dedicating to exploring the new markets and seeking for mutual benefit and win-win state with our customers.

![]()

![]()