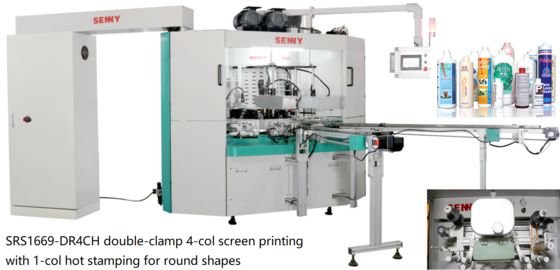

6-Color 80 Pcs/Min Soft Tube CNC Automatic UV Printing Machine

Product Details:

| Place of Origin: | Dongguan China |

| Brand Name: | SENNY |

| Certification: | CE SGS |

| Model Number: | SRS1669 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1PC |

|---|---|

| Price: | negotiation |

| Packaging Details: | Plywood package |

| Delivery Time: | 45days |

| Payment Terms: | T/T |

| Supply Ability: | 10 pcs/month |

|

Detail Information |

|||

| Model Number: | SRS1669 | Auto Grade: | Fully Automatic |

|---|---|---|---|

| Printed Color: | 6 Colors | After-sales Services: | Video Or On-line |

| Brand: | Senny | Plate Type: | Screen Printing Machine |

| Highlight: | 6-color Automatic Screen Printing Machine With A Printing Accuracy Of ±0.1 Mm, Capable Of 360-degree Printing. It Features Flexible Printing Performance And Comes With A 1-year Warranty. | ||

| Highlight: | 6-color CNC UV printing machine,80 pcs/min tube printing machine,automatic soft tube UV printer |

||

Product Description

6-Color 80 Pcs/Min CNC Soft Tube Automatic UV Printing Machine

Machine Feature

- This machine is suitable for multi-color UV ink screen printing on plastic soft tubes and can also handle decorative processes like hot stamping and varnishing, meeting the varied decorative needs of different product surfaces.

- With an integrated turntable design, it uses the same set of fixtures to finish all printing functions. It has a printing accuracy of up to ±0.1mm, which effectively guarantees consistency in mass production.

- Powered by a numerically controlled servo motor, it allows 360-degree all-round printing on products. It also comes with remote management and service functions, in line with the Industry 4.0 development trend and helping enterprises achieve intelligent production management.

- It is fitted with electrical components from well-known brands, along with a PLC control system, an easy-to-use touchscreen and wireless tablet operation. This ensures stable and reliable performance while greatly lowering operation difficulty and maintenance costs.

![]()

Optional Configuration

- Unscrambling & Feeding Machine: It automatically sorts and arranges printing substrates like plastic hoses and metal cans, then conveys them precisely to the next step. This eliminates the errors and inefficiency of manual feeding, providing a stable basis for subsequent printing.

- Hot Stamping Function: It creates metallic or colored hot stamping effects on product surfaces and works with different hot stamping foil specifications as needed. This boosts the visual layers of printed items and elevates the high-end look of product packaging.

- Plasma Surface Treatment Function: Using plasma technology, it cleans oil stains and impurities from product surfaces and enhances substrate surface tension. This fixes the issue of poor ink adhesion on plastics, glass, and other substrates, keeping patterns from peeling easily.

- Visual Registration Function: Via a high-definition visual recognition system, it tracks product positions in real time and auto-calibrates the alignment between printed patterns and substrates. Even for irregularly shaped products, it prevents printing offset, raising finished product qualification rates.

- LED-UV Curing Function: It uses an eco-friendly, energy-saving LED-UV light source to quickly cure UV inks. Compared to traditional curing methods, it’s faster, emits no harmful volatile substances, and avoids high-temperature damage to substrates.

- Finished Product Quality Inspection Function: It uses image comparison to automatically check finished products for issues like unclear patterns, color differences, and defects. Replacing manual checks, it cuts down on missed and false inspections, ensuring consistent quality across batches.

Technical Parameters

| Machine Model | SRS1669 |

| Printing Color | 6 |

| Printing Speed | Up to 80 pcs/min |

| Soft Tube Diameter | 15-75mm |

| Soft Tube Height | 60-220mm |

| Max.Printing Length | 220mm |

| Max.Printing Height | 180mm |

| Printing Accuracy | ±0.1mm |

Senny provides services for multiple industries, including food, pharmaceuticals, toys, cosmetics, daily chemicals, electronics and decorative products. It applies a range of automatic printing technologies—such as screen printing, pad printing, hot stamping, labeling, offset printing and digital printing—to print high-quality, exquisite graphics and text on the surfaces of products with different shapes, which are made from materials like plastic, metal, glass and ceramics.